Interview with a Bridgestone Tyre Engineer: A Behind-the-Scenes Look at the World of Motorcycle Racing

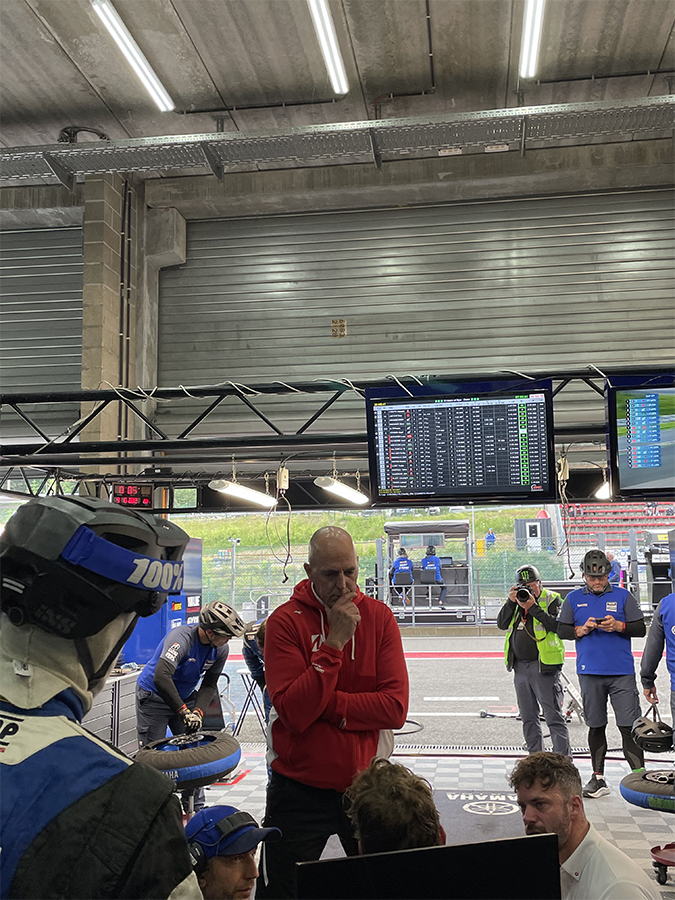

Motorcycle racing is a high-octane world where every millisecond counts, and behind each successful race team is a meticulous tyre engineer. We sat down with Peter Baumgartner, also known as “Pit”, the leading motorcycle tyre engineer at Bridgestone in the Endurance World Championship, to uncover what fuels his passion, the intricacies of his role, and the challenges he faces in the fast-paced environment of motorcycle racing.

What initially sparked your interest to become a tyre engineer?

“When I was a racing mechanic of 20 – 21 years old, I was inspired by the tyre engineer’s work and responsibility. I wanted to step into that role to advance in the motorcycle racing environment,” he explained. “Seeing engineers with their binders walking around the paddock, I knew that’s what I wanted to do.”

Who or what inspired you to get into motorcycle racing?

“During a visit to the Hockenheim GP race in 1989 with my motorcycle, I managed to enter the paddock area and asked Martin Wimmer, a GP250 rider, for a job,” he recalled. “Wimmer was my hero. Initially, I planned to ask for his autograph, but I ended up asking for a job instead. I started out as a fan.”

Some background information: Martin Wimmer, born on October 11, 1957, in Munich, is a former Grand Prix motorcycle road racer from Germany. In the 1980s, it wasn’t uncommon for GP riders to help with the wrenching, as Wimmer often did. He had a decade-long GP career, primarily in the 250cc class, winning a total of three 250cc GPs. His best year was 1985, when he won the German Grand Prix, secured two second places, and finished the 250cc season in fourth place.

What do you find most rewarding about your job as a tyre engineer and why?

“Taking responsibility and ensuring the highest level of security and performance for the team and rider is incredibly rewarding,” he shared.

Can you describe the collaboration between the tyre engineer and the race team to maximize tyre performance before a race?

“Within the team, it’s like a triangle: the tyre engineer and suspension engineer, and crew chief work closely to define and analyze rider comments and telemetry data,” he explained. “This collaboration helps us find the best possible solution to provide a safe and performance-oriented outcome with the optimal tyre combination. Changing the tyre affects the motorcycle settings, so it’s about finding the best package.”

What is the importance of tyre testing and analysis during the preparation phase?

“Data is everything. Tyre testing, prototype testing, telemetry data, and rider input lead us to choose the best tyre and make the right adjustments,” he said. “We start with a reference, define a target, and make decisions. More grip isn’t always the target; tyre stability and durability are crucial too. Track conditions and temperatures vary greatly, so we need to ensure tyres perform well from 5° at Le Mans at night to 55° at Suzuka.”

Could you explain on what basis you decide to choose the selection of tyres and how it affects performance during the race?

“Tyre selection is based on several factors: track layout, corner typology (type of corner, for example: closed corner, open corner, 90 degree corner), tarmac mu (means grip index of the asphalt: roughness of the asphalt and the grip level), possible weather conditions, and other confidential topics. We also rely heavily on our experience.”

How do you ensure the tyres are a proper match to the specific track conditions?

“Before any race event, we evaluate the track using internal measures and experience. We look at the track layout and decide whether to go softer or harder based on the corners,” he noted. “Historical data, track layout, weather forecast, and knowledge of the rider and bike all play a part.”

How do you monitor the performance of the tyres during a race?

“Lap time is a clear confirmation. In EWC racing, there are 10 to 27 outs/ins, so lap times are crucial. After pit stops, we check tyre inner pressure, visual wear-appearance, and temperature,” he detailed.

What actions do you take when something goes wrong with the tyres during a race?

“As soon as the race week starts, we have a backup plan prepared on paper or in mind. We have plan A, B, C, and sometimes D. This is your life insurance in the garage.” he said. “For instance, during the Bol d’Or 2023, it unexpectedly rained on Saturday. I went to work four hours earlier to write down all possible scenarios, solutions, and consequences. All plans A, B, C, and D were used during that race.”

Can you give an example where your decisions as a tyre engineer made a big impact on the final results?

“At the Estoril 8H Race in 2020, I decided to use a tyre that wasn’t the riders’ first choice. After the second stint, due to a too slow lap time, I changed the tyre. Our lap times improved, and we won the race,” he remembered. “I have many examples but this one is my favourite as the tyre I used was not preferred by the rider. This decision highlighted the importance of the relationship and trust between the engineer and rider.”

What is the biggest challenge during an EWC race for you as a tyre engineer?

“Ensuring the running condition (controlling all measures around preparation), providing solutions in difficult situations, and being able to change tyre choice due to changing ambient/track temperatures to ensure the highest safety to the rider while keeping the performance up. Versatility is key in EWC races, with many pit stops and changing conditions.”

What is the difference with sprint racing?

“Sprint racing (Superbike, MotoGP) focuses on maximum performance over a short time, usually ranging from 15 – 40 minutes and between 8 – 24 laps, with no pit stops. The tyre engineer makes decisions based on free practice and qualifying results. In endurance racing (such as EWC and national endurance racing), races are longer, with more pit stops and changing conditions. As an engineer, you must consider temperature, day/night transitions, weather, and corners, making it more challenging. Endurance racing is a higher level of complexity.”

How do you collect data from the performance of the tyres during a race and how does this impact the future of tyre engineering?

“After practice and during the race, we first collect rider comments, then we check the telemetry data to re-check and re-confirm the rider’s comments. We check the tyre temperature, inner pressure, and visual wear. This data helps us improve or change tyre performance and consistency for future races,” he explained. “EWC testing is also crucial for the development of our mass production racing tyres, which can be bought by anyone.”

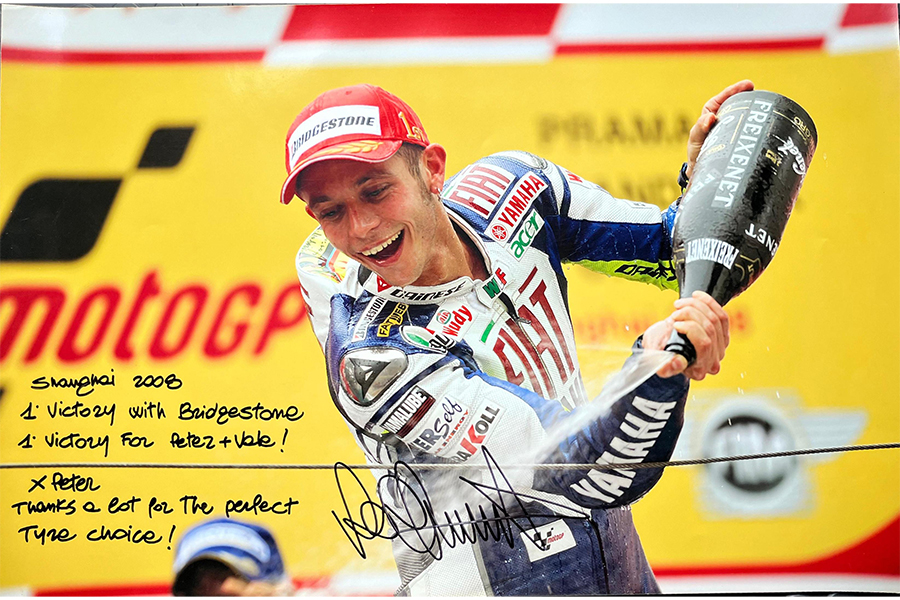

What was the most memorable race of your entire career and why?

“The 2008 Shanghai race with the Yamaha Factory Team and Valentino Rossi was memorable. I decided to use a rear tyre we had never used before, which resulted in my first MotoGP victory and Yamaha’s first win on Bridgestone tyres with Rossi,” he fondly recalled.

How do you learn as a young engineer and get to that level?

“At Bridgestone, young engineers are given clear responsibilities and the confidence to make decisions. This is the same approach I use to teach young engineers now.”

This in-depth conversation with Pit offers a glimpse into the dedication and precision required in the world of motorcycle racing. From the initial spark of inspiration to the planning and real-time decision-making, it’s clear that tyre engineering is both an art and a science, crucial to the success and safety of racing teams worldwide.